- Single Bevel vs Double Bevel Miter Saw: When to Use Each - June 24, 2022

- Best Paint Scrapers: How To Find The Right For The Job - June 24, 2022

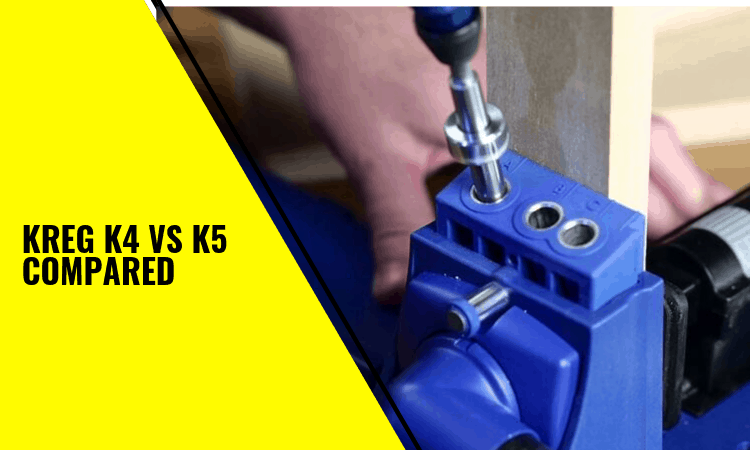

- Kreg K4 vs K5 Compared: Which Is Best For You? - June 24, 2022

Trying to get all of your materials in the correct position before machining them into the exact shape or structure that you need can be difficult without some assistance. There are a lot of different tools and pieces of equipment that you can use to ensure your tools remain in the correct position for fabrication and cutting along with any other type of work project that you may be working on.

When it comes to working with metal, wood, and other types of material, it’s a no-brainer for you to keep your tools and work materials in a uniformed and stable position so that you can optimize your work efficiency and precision. For experienced woodworkers and other material fabricators, you’re probably familiar with jigs and how they operate.

Jigs are devices that are used to stabilize other tools and materials. Commonly, wood is the most used material format when talking about jigs. The best way to describe a jig is essentially an open frame or plate that is used for holding work materials and assisting machining tools while guiding them in the right direction during operation.

One of the most popular uses for jig devices is spacing and locating drill holes, that’s because it provides you with an accurate measurement device by which you can gauge if whether or not your current materials will be compatible with the design you’re aiming for.

The primary purpose of a jig is to allow woodworkers and other material fabricators the ability to repeat precise action, cuts, and other modifications in addition to allowing them to interchange the format and positioning of their work without compromising quality during the manufacturing phase.

Jigs can also be used to guide or hold tools such as drills and saws during the material fabrication stage to ensure that precise adjustments are made.

There are several different types of jigs available on the market today however they all are designed with specific use purposes and material working applications in mind.

Main Differences Between Kreg K4 vs Kreg K5

The Main Differences Between Kreg K4 vs Kreg K5 are:

- Kreg K4 designed for use by DIY woodworking fabricators, whereas Kreg K5 is best for enhanced pocket joinery machining.

- Kreg K4 contains a durable toggle clamp, whereas Kreg K5 includes a swiveling dust collector port.

- Kreg K4 is more affordable, whereas Kreg K5 is more advanced and powerful.

- Kreg K4 good for small places and projects, whereas Kreg K5 works great on large scaled pieces.

Two of the most popular types of jigs currently out are the Kreg K4 and K5 jigs, and both of these jigs were designed with very specific uses and material working applications in mind.

If you’re a woodworker or any other type of material fabrication specialist and have been comparing both of these jigs to decide on which one is right for you, you’re in luck. In this guide, we’re going to go over all of the core benefits, features, and capabilities offered by both of these jig rigs.

After taking an in-depth look at both of these jig options, we’ll also give you our honest opinion about whether or not you should waste your time and money by using them so you can make an educated purchase decision and find the one will suit your needs best.

Our personal favorite is the Kreg Jig K5.

For an extra $25, you get a much more complete and efficient Jig.

This is due to the K5 is packed with additional features and is easier to use all around, but we will touch more on this later.

To begin, let’s take a look at exactly what jig rigs are and how they can help you make more accurate, clean, and uniformed fabrications while working with materials.

What is a Jig?

A jig is a tool accessory that often comes in the shape of a frame or plate, they all have different designs and features all depending on their intended user base however they will commonly feature pre-drilled holes, precisely machined edges, and more.

All of which work to assist you in making consistent and repeatable material fabrications. Jigs come in all different sizes and shapes which allow you to get the exact material fabrications that you need without having to worry about manually adjusting or aligning any of the components.

Jigs can also be used to ensure the stability and positioning of tools like saws and drills as they help guide the tools in the desired direction. These devices are commonly used by woodworker and other material fabrication specialist who need to make precise cuts and other adjustments to pieces of material for their work or DIY projects.

Now that we’ve gone over exactly what a jig is and how you can use it for your material fabrication needs, it’s time to look at exactly who the Kreg K4 and K5 were designed for.

Who is the Kreg K4 and K5 for?

While both the K4 and K5 have very similar features and overall design elements, they do differ in some key areas that you need to be aware of. Both the K4 and K5 were designed for professional woodworkers and other material fabrication specialists. However, different people will find beneficial uses in each model that favors their particular type of work when compared to the other one.

The K4 model was designed for use by DIY woodworking fabricators as it has an easier to use interface which makes tasks such as pocket joinery more efficient. Because of the K4’s design, it provides an assistive tool that makes all of your essential woodworking tasks almost effortless. It contains a lot of intuitive design features like a durable toggle clamp and much more.

The K5, on the other hand, was built for enhanced pocket joinery machining that professional woodworking can use and benefit from. The K5 model also has a lot of other integrated capabilities such as a swiveling dust collector port which makes it simple and easy for you to maintain a clean work environment.

It features a lot of the same design elements as the K4 however they are more advanced and powerful which makes it perfect for pro material fabrication workers.

Now that we’ve gone over exactly who the K4 and K5 were designed for, it’s time to take a look at the history behind the company who produces both of these jig options.

History Behind The Company: Kreg

Kreg has a very rich history in the tool industry particularly when it comes to their jigs and other sorts of tool and work accessory options that they provide. Because of their incredible track record over the years, Kreg has become one of the largest and most trusted tool accessory manufacturers in the world.

Kreg was started in 1986 by Craig Sommerfield who at the time of inventing the company was in the process of building a home for himself, during the building process Craig encountered a few issues.

One of the main problems he faced when building his home is that he didn’t have access to a device which would allow him to properly connect his dowelled face frame to the kitchen cabinet carcass he was installing.

Since he didn’t want to nail the face frame to the kitchen cabinets and fill in the loose holes with caulking, he designed the first-ever “Craig’s Jig” which had a single-hole pocket-hole jig that was made out of a combination of aluminum and steel.

This unique invention allowed Craig to install his face frames to the interior of his kitchen cabinets while hiding the joints which connected the two pieces from within the view.

After seeing the genius ingenuity and engineering on display by Craig, many of his close coworkers and friends motivated him to build more of the jigs which he eventually did. He would go on to produce multiple replicas of his unique and newly invented jig tool to people at local woodworking shows in his area.

He would continue this same pattern for several years until he finally founded the Kreg Tool Company that woodworkers and other material fabrication specialists love and know today.

Kreg tool products are available in many different countries and regions across the world including the UK, Canada, the United States, and Australia.

Now that we’ve gone over all of the most important historical facts about Kreg, it’s time to take a look at the main differences between the K4 and K5 jig so that you can make sure you’re choosing the correct model for your specific needs.

Key Differences and Similarities Between Kreg K4 and K5

Both the K4 and K5 come packed with a lot of different features and capabilities which will allow you to take on all of your pocket joinery tasks with ease. However, both of these models also come with very distinctive functions that vary from one another.

In order to make the right decision about which one of these jig models will provide you with the functionality and versatility that you need, you need to become educated as to how they differ in their feature sets and modes of use.

Below, we’re going to provide you with a side by side comparisons of the K4 and K5 so that you can get a more realized view into the specific features and options that both of them come with.

|

Kreg K4 |

Kreg K5 |

|

|

As you can see, both of these jigs offer very different types of features however they are very similar in their design elements. By simply looking at the table above, you will be able to see which one of these variants offer the type of power and functionality that you need to complete your work efficiently and precisely.

It’s really important for you to consider your personal needs and work style when selecting which jig model is best for you because everyone has different preferred styles and material working approaches that need to be complemented with compatible accessories

Now that we’ve gone over some of the main differences between the K5 and K4, it’s time to look at an overall view of what you can expect when choosing either of these jigs for your next material working project.

Feature Overview: Kreg K4 vs K5

When it comes to the overall features offered by the K4 and K5, some very robust and intuitive capabilities come as integrated capabilities on both models.

What separates these two models are their applications, each one has unique machining functions that will be very specific to certain types of woodworkers and fabricators.

In the following section, we’re going to provide you with an overall look at what both of these jig models have to offer for your particular project so that you can be sure it will help improve the accuracy, efficiency, and results of your work.

K4 Overview

The K4 is one of the older mode jig variants produced by Kreg, however, it still has many useful purposes and functions that can be applied to modern building techniques.

Kreg K4’s was made primarily for drilling pocket holes with increased accuracy and precision, however, it is also outfitted with a lot of design elements which make operating and using the jig very easy for material workers of all experience levels.

The K4 is perfect for working on small pieces of material and even some larger pieces which makes it a very versatile and capable jig option.

You will gain the most benefit from using the K4 when operating on small material pieces as that was what it was originally designed for. You can adjust the jig to meet various material thickness levels which allows you to experiment with what feels comfortable for you while using the device.

This jig also has a fast clamping system which makes it easy for you to secure the device while in use. The K4 is also compatible with different Kreg branded attachments and accessories which allows you to expand the current capabilities of the device quite easily.

The K4 also has an integrated drill guide that can be removed for increased mobility of the tool when needed. In essence, the K4 is a 3-hole drill guide makes it easy for you to make precise cuts and incisions in different materials. The K4 is made for a DIY project and those interested in carrying out home improvement projects on their own.

K5 Overview

The K5 is essentially an upgraded version of the K4 model that packs much more power and functionality options. This model provides beneficial integrations that professional woodworkers can utilize when working on their various projects.

The K5 is packing a front-mounted handle that makes it easy to adjust the precision and angling of this jig, it also has a built-in clamping system that you won’t find on the K4 model. The built-in clamping system on the K5 also incorporates a ratcheting function that allows you to independently adjust the jig configuration.

Another advantage that the K5 has over the K4 is that it comes with an onboard storage wing which makes it easy for you to access and store all of your needed accessories with no extra attachments.

The K5 is also a lot larger than the K4 so this is something to consider if portability is a big factor for you, another factor you want to consider is that the K5 is rated to support larger pieces of materials than the K4 so if you consistently fabricate large pieces of wood, you’ll want to select the K5.

Now that we’ve covered a brief overview of both of these jig devices, it’s time to look at a more in-depth review of exactly what benefits they have to offer woodworkers of all sorts.

For just about $25, you get a much more complete and efficient Jig packed with a ton of features and allowing for overall easier use. The Kreg K5 supports larger pieces of materials, has an in-built clampling system, and comes with an onboard storage unit to store essential accessories.

In-Depth Review: Kreg K5 vs K4

By now, you know a little bit more about all of the capabilities and features offered by both of these jig options, however, you don’t know exact details.

In the following section, we’re going to explore all of the specific design elements and details about the features that both of these jigs offer so that you can make an educated decision about which one is best for you.

K4 In-Depth Review

Dust Collection

One of the main cons of the K4 is that it does not come with any sort of integrated dust collection capabilities or features. When you’re working on your various material projects, you will just have to deal with all of the sawdust from the wood falling onto the floor and you have to sweep or pick it up.

If this is a major issue for you, you may want to go with another option.

Clamping Features

That K4 comes with a large clamping mechanism that allows you to easily secure the tool and any materials that you may be working on. The clamping mechanism makes it easy for you to secure the accessory to your workbench for enhanced precision cutting and machining all together.

Features

The K4 has a finely tuned drilling angle that allows you to efficiently cut through pieces of wood while safeguarding you from making mistakes in the size of the pocket hole being too large.

It also has an integrated wood-chip relief feature for every hole in the device, this ensures that no wood chips are able to accumulate inside of the drill itself. This feature also helps to reduce the amount of drill torque that you experience and it also increases the overall lifespan of the drill bits you use.

The jig also has a rear-mounted clamping mechanism that allows you to maintain a solid angle and position regardless of what you’re clamping your jig to. You can also easily adjust the overall configuration of the jig by simply releasing the locknut mechanism and then rotating it to the desired setting you desire.

Pricing

The K4 is very affordable as it only costs about $100 and often times less all depending on the retailer that you purchase it from. This is great because those woodworkers who need one of these tools can easily pick them up without having to dish out too much money.

The Kreg Jig K4 is our best choice overall. It's a durable tool that's easy to use, so whether you are a beginner or an expert, it will get the job done. The price is very affordable, and there is everything you need in the kit.

K5 In-Depth Review

Dust Collection

The K5 is equipped with a removable dust collection port that can swivel on either side of the jig making it very convenient and easy for you to clean up after every project.

Most jigs come with a standard rugged dust collection port however the swivel ability of the K5 puts it far beyond the competition in the same category.

Clamping Features

The K5 has a built-in K5 clamping system that makes it easy for you to attach the tool to the tabletop. This ensures that you do not need to purchase any extra accessories or attachments just to secure your jig to your work station.

Features

The K5 makes it easy for you to adjust the thickness level of the jig by using it’s ratcheting mechanism to position your materials in the correct position. The adjustment feature slides into place which only requires you to lift the handle until you hear two clicks to signal that it is in a secure and stable position.

It’s also capable of handling very large pieces of materials which makes it great for professional woodworking and material fabrication. It has very large support wings that can attach on both sides of the jig conveniently.

These support wings will be able to keep your work materials in one stationary position. Another great benefit of the K5 is that it comes with an integrated storage space that allows you to easily store drill bits, screws, and more. Its front-mounted handle makes it easy for you to utilize all of the features that come with this jig.

Pricing

The K5 is more expensive than the K4 model however it packs a lot more capabilities and features than its relative. For around $125 you can purchase a K5 and receive a lifetime warranty from the company itself so that you never have to worry about being without an essential tool that you need to work on materials.

Now that we’ve covered all of the in-depth features and capabilities of both of these jig selections, it’s time to give you our honest opinion about which one of these jig variants we feel like is worth the money.

Our Decision

Both the K4 and K5 pack a lot of very useful and advanced features that woodworkers at all levels will appreciate. When it comes to deciding on which one of these models provides the most value to you the end-user, there are several different factors that you have to consider.

These two jig variants were designed with very specific material fabricators in mind, because of that, they both provide distinct benefits to users who have preferred work styles and methods.

The K5 is by far the more powerful and capable jig option out of the two however some people may not need all of the power and functionality that it offers. The K4 is less costly and smaller than the K5 however it may not provide the material capacity and convenience that the K5 does.

Choosing between which one of these models is best for you will ultimately come down to how you work on materials and what your primary needs are as they relate to what you expect out of a jig.

If you’re a professional woodworker or material fabricator looking for a powerful and durable jig that can handle large projects, the K5 is probably the best model for you to go with.

If you’re an individual who only wants to perform simple home improvement tasks yourself whilst still having the reliability and functionality of a professional-grade tool, the K4 may be the best selection for you.

Always consider your individual needs and requirements as they relate to the key features you need out of a jig in order to make the right purchase decision.

Now that we’ve given you our opinion about which one of these jig models we feel is best, it’s time to answer some of the most commonly asked questions that people have when it comes to Kreg jigs.

FAQ’s

Although you know a lot about the K4 and K5 jigs, you may still have some questions in regards to use and other related information. In the following section, we’re going to answer some of these questions so that you can go into making your buying decision confidently.

Do they come with a warranty?

Yes, all Kreg jigs and other products are covered by a lifetime manufacturer warranty.

Which one is easiest to use?

Both are easy to use it all depends on the type of materials you’re working with and their size.

What materials can I use with them?

These jigs are primarily used for woodworking however you can use them to cut a hole in anything.

Conclusion

Use all of the information in this guide to help you make the right decision about whether the Kreg K4 or K5 is the best jig selection for your specific needs.

Everything that you need to know about their features and capabilities is listed all throughout this article so uses it as a resource to gain all of the knowledge that you need to begin curating precise holes and alignments with ease.

For just about $25, you get a much more complete and efficient Jig packed with a ton of features and allowing for overall easier use. The Kreg K5 supports larger pieces of materials, has an in-built clampling system, and comes with an onboard storage unit to store essential accessories.