- Eastwood TIG 200 Review: All You Need to Know! - June 25, 2022

- Best Drywall Sanders – How to Find Them and Which to Buy - June 25, 2022

- Makita vs Dewalt Drill – Which is the Best Brand? - June 24, 2022

It’s a dilemma that many a novice woodworker has faced when they first start out: Should you use a jointer to properly prepare your lumber for that next big project, or will a quality wood planer do the job just as well? Of course, as any seasoned craftsman would happily tell you, the real answer to the whole jointer vs. planer debate isn’t really about picking one over the other at all.

Rather, it’s about overcoming the common misconception that the two are essentially different tools that fulfill the same basic purpose and understanding that both products do very different jobs. As such, you’re likely to find that the best results usually come not from picking one tool over the other, but using both on the same board.

Not that either one is always necessary essential.

These days, it’s much easier to purchase S4S lumber that comes perfectly surfaced on each side so that it’s ready to use right off the shelf, meaning there’s no need to joint or plane it/ That being said, even though S4S is more readily available than it used to be, it still isn’t nearly as common as good old fashioned rough cut lumber.

So, if you’re purchasing that kind of wood for your next project, then it pays to get the bottom of this whole jointer vs. planer argument once and for all.

That’s exactly what we’re about to do today.

Below, we’ll explain the difference between these two useful pieces of machinery as well as offering our advice on when and why you might want to use each one.

That’s not all.

We’ll also offer our picks of the very best jointers and planers currently on the market, as well as answering your burning questions about both products. Before we dive into that, however, let’s first take a brief look at exactly why the two are so different.

On the face of it, it doesn’t come as much of a surprise to learn that many inexperienced woodworkers and DIY beginners see jointers and planers as basically the same thing.

After all, both are used to alter the surface of lumber, and both use a rotary drum with mounted blades (often called knives) to do their jobs.

Yet that’s just about where the similarities begin and end.

Here’s a look at the main differences between jointers and planers.

Main Differences Between Jointers vs Planers

The Main Differences Between Jointers vs Planers are:

- Jointers are used to perfectly square a single edge and flatten a single face, whereas planers are used to ensure a consistent thickness and create parallel surfaces.

- Jointers can finish boards to roughly the same thickness, whereas planers can ensure that boards have the exact same thickness throughout.

- Jointers have knives mounted in the table that cut the wood from below, whereas planers cut from above.

- Jointers can remove warping and cupping, whereas planers are slightly more expensive.

In a nutshell, using a jointer is useful for starting to prepare your wood for a project. It will give you one perfectly flat face and square up to one edge of the wood so that it can connect with other boards (such as when you’re creating a table or bookshelf). However, if you want all faces and edges to be parallel and consistent (which you do if your finished project is going to be of durable quality), then a planer is the way to go.

In a moment, we’ll dive deeper into the details about what each machine can actually do but, first, let’s answer another very important question.

Why do I Need a Jointer or Planer?

Again, you might not need either machine at all if you can get wood that has already been pre-finished.

In some cases, you can buy S4S lumber directly. Alternatively, some lumber yards may be prepared to prepare the surface of your boards before they deliver them.

In most cases though, you’ll be heading to your local lumberyard or DIY store and picking up rough, unfinished wood which, while strong and durable, simply isn’t fit for building with until it’s been treated.

At best, rough-cut wood can have uneven surfaces which make jointing them a challenge. At worst, storage conditions can leave that wood warped, twisted or cupped, which leaves it unusable.

It’s for this reason that many experienced craftsmen consider jointers and planers to be among some of the most essential woodworking tools in their arsenal.

A good jointer can remove that warping or twisting, while a planer can smooth off surfaces and leave each board perfectly ready for use.

What is a Jointer?

A jointer is a heavy-duty piece of machinery that is used to ensure that the edge of your wooden boards are straight and square so that they can be joined together to create a much larger board.

Of course, it is possible to do this without a jointer by moving a hand plane across the wood rather than moving the wood through the machine as you do with a motorized jointer.

Yet to do this takes a certain level of skill that has to be built up over time and even those who have mastered the art of doing it manually admit that it’s a fairly time-consuming process.

Using a jointer makes squaring edges quickly and practically effortless, but that’s not all that they do.

They also prove invaluable at removing twists, warps, or cupping from your boards.

Pros of Jointers

- Much easier than squaring edges by hand

- The quickest way to remove twisting and warping

- Fully adjustable so that you can change the angle of the cut to suit your needs

- Typically less expensive than planers

Cons of Jointers

- No way to guarantee consistent thickness across the board

- Still leaves rough faces which are better treated with a planer.

Top Three Best Jointers

Ready to buy the best Jointer for your job? These are the three models that currently offer the best value for your hard-earned money.

|

Rank |

Name |

Weight |

Price range |

|

1. |

76 lbs |

$500 – $600 |

|

|

2. |

40 lbs |

$250 – $350 |

|

|

3. |

81 lbs |

$300 – $400 |

1: Delta 6” Bench Top Jointer 37-071

Retailing for between $500-$600, there’s no getting away from the fact that Delta Power Tools excellent six-inch MIDI-Bench Jointer is one pricey bit of kit.

Yet despite being one of the most expensive power tools we’ve ever featured, it’s still well worth the investment if you take your woodworking projects seriously.

By holding two blades instead of one, the six-inch-wide cutter head allows for much faster cutting of 1/8″ depth at a rate of up to 20,000 cuts per minute.

If you need to make adjustments, then you’ll find the straightforward jackscrew arrangement very easy to use.

Elsewhere, you’ll find a solid, cast-iron fence that delivers positive stops at both 90° and 45° on either side to create the most precise cuts of any jointer we’ve come across.

One of the most consistently well-reviewed products of its type, this sturdy, highly durable benchtop joiner is ideal for smaller workshops where space is at a premium.

What’s more, it’s incredibly simple to set up and start using, making it a great choice if you’re just getting started in woodworking.

Durable cast iron construction increases weight providing stability and reducing vibration. Precision-machining of the table and fence ensures long term accuracy. Heavy duty, cast iron fence support system for accurate jointing.

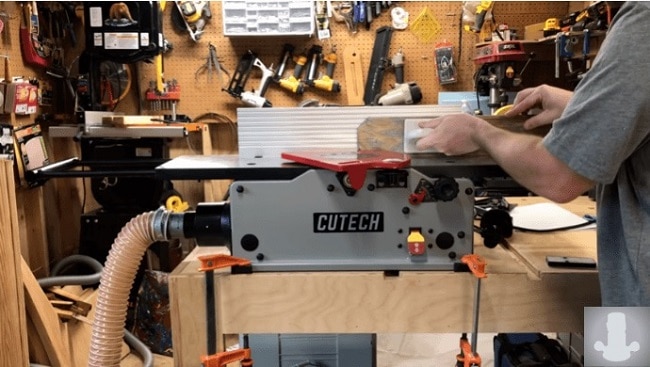

2. Cutech 40160H-CT 6″ Bench Top Spiral Cutterhead Jointer

If you need a quality jointer on a budget, the Cutech’s powerful Jointer 40160H-CT model may be just the thing.

Though prices will always vary from retailer to retailer, we’ve yet to see this model going for more than $350. While that may seem like a hefty price tag, you can take our word for it that this is about as affordable as you’re going to get for one of these power tools.

Not that affordable necessarily means cheap. Honestly, there’s nothing cheap about this highly durable, well-constructed model.

The perfect combination of professional-grade cutting and newcomer-friendly operation, the Cutech 40160H-CT will be just as home in a commercial workshop as it would be in the garage of an amateur enthusiast.

At its core, a powerful 10-amp motivator drives a modified spiral cutter head which ensures a remarkable finish every time.

As with all the best jointers, this one is fully adjustable and can be tilted from 90° to 30° depending on your requirements.

A hidden highlight of this six-inch benchtop model is that it’s surprisingly lightweight. At only 40lbs, it packs barely half the weight of our other top two models.

Sure, this may not seem like a big deal for a benchtop power tool, but it does come in very handy if you decide to upgrade your garage workshop or even if you decide to lend it out to a friend.

Powerful 10 Amp 120V motor. Spiral Cutterhead with 12 HSS Inserts. Fence with 90 to 135 Degree Tilt.

3. Grizzly G0725 6 by 28-Inch Benchtop Jointer

As one of America’s leading manufacturers of premium brand wood and metalworking tools, it’s no surprise to find that Grizzly is responsible for one of the most accurate and user-friendly motorized jointers currently available.

The pièce de résistance of their range of critically acclaimed, commercially successful woodworking tools, the Grizzly G0725 certainly packs a sizable punch.

At 80 lbs, it’s the heaviest jointer on our list, but most of that weight is down to the superior quality of its cast iron construction and Grizzly’s trademark commitment to making products that are built to last for years.

The whole thing is driven by a mighty 110 Volt single phase 1-1/2-horsepower motor that allows the cutter head to make flawless, precise cuts at speeds of up to 10,000 rotations per minute.

The only reason we haven’t ranked this higher is that, while the G0725 is definitely fast and powerful, it’s not possible to reduce its speed, something which would be useful for some projects.

Despite that, there’s still a lot to like about this one.

For one thing, it’s fully adjustable within 45°, though perhaps the one thing we like best is that it’s remarkably simple to use, making it another solid option for novices.

Motor: 1-1/2-HP, 110V, single-phase, cast iron table. Cutterhead speed: 10, 000 RPM.

What is a Planer?

After running your board through a jointer, you’ll be left with one flat surface and one perfectly squared edge.

So far, so good, but how do you deal with the remaining surfaces and edges?

Sure, you could always run that same board through the same jointer over and over again, but not only is that rather laborious, it’s also pretty ineffective.

Using a jointer, it’s nigh on impossible to ensure that all surfaces are parallel or of a consistent thickness.

This is where a good-quality planer proves to be invaluable.

At the core of this particular machine, you’ll find a flatbed for your board to ride on, with a cutting head positioned above it. By using input and output rollers to manage the speed at which the board passes through the cutting head, you’re guaranteed a much more precise, consistent, and smooth finish than you’d get from a jointer or even a hand plane.

Pros of Planers

- It offers the easiest way to create parallel surfaces

- Best choice for consistent thickness

- Much easier to use than hand tools

- Provides an overall smooth finish that you don’t get if you only use a jointer.

Cons of Planers

- Not able to remove warping, twisting, or cupping

- Sometimes have to pass your lumber through the machine multiple times to achieve the required level of thickness

- Not suitable for squaring off edges

- Can be very expensive, even more so than jointers.

Top Three Best Planers

If you’re thinking of buying a Planer, these are the one’s that we recommend

|

Rank |

Name |

Weight |

Price Range |

|

1. |

80 lbs |

$450 – $500 |

|

|

2. |

61 lbs |

$600 – $700 |

|

|

3. |

82 lbs |

$450 – $550 |

1: DeWalt DW734, 12-1/2” Thickness Planer

We’re not the only ones to rank the exceptional DeWalt DW734 so highly.

Combining ample power with unrivaled precision, this high-performance model consistently earns rave reviews from both industry insiders and enthusiastic hobbyists alike.

It comes with a strapping 15 amp motor capable of driving the unique three-blade cutter head at speeds of up to 10,000 rotations per minute.

This creates 96 cuts per inch of 1/8″ depth which, all told, allows for one of the smoothest, most precise finishes you’re likely to get.

If you regularly cut to the same thickness, a turret depth stop allows you to preset at that size to make your work much easier and ensure the highest levels of accuracy of any motorized planer we’ve seen to date. Read our full DW734 review here.

The Dewalt DW734 is a great choice if you are a DIY enthusiast and you are looking to buy a high quality planer for your home improvement projects. However, it is not the best choice for professional and commercial use and heavy-duty work.

2. Makita 2012NB 12″ Planer

There are some professionals out there who will tell you that the Makita 2012NB 12-Inch Planer with Interna-Lok Automated Head Clamp offers even better performance, precision, and power than our number-one ranked Dewalt model.

We don’t necessarily agree with them, but you can certainly see why their argument is so compelling.

Like the Dewalt, this one is powered by a 15 amp motor, this one driving a two-blade cutter head for a maximum no-load speed of 8,500 RPM.

Elsewhere, the 2012NB comes with a top-end 28 feet-per-minute feed rate and can plane boards of up to 12″ wide, 1/8″ deep and 32 inches thick.

In our experience, it creates a remarkably fine finish, yet even that isn’t what sets the Makita 2012NB apart from the crowd.

No, that honor goes to its outstanding efficiency and quiet operation. The two blades can be changed and adjusted with incredible quickness.

What’s more, you can rest assured that even when this one is going at full throttle, it will never be louder than 83 decibels, a feature which is no doubt good news if your workshop is located in close proximity to your neighbors.

Compact with less weight for easy transporting to the jobsite. Engineered for faster, easier blade changes.

3. Delta 22-590 Portable Planer

The Delta 22-590 is the heaviest model in our list, which doesn’t exactly make it the ideal choice in terms of mobility and portability.

However, with even the most expensive options coming in at under $550, it’s also one of the most affordable, making it a great value option for woodworkers looking to build up their workshop on a budget.

Capable of creating deep, accurate cuts on boards up to 13” wide and 6” thick, the Delta 22-590 has a three-blade cutter head that is built to go the distance.

Delta boasts that their blades last up to three times longer than other three-knife models, and so far we’ve found no evidence to dispute that fact.

The other main feature of the cutter head is Delta’s patented lock system and specially designed infeed and outfeed table which ensures minimal snipe.

Though it certainly has its drawbacks and doesn’t quite match the performance of our higher-ranked options, you certainly won’t be disappointed with the 22-590.

Three Knife Cutter Head provides an ultra-smooth finish and up to 3 time longer blade life than competitive 3 knife planers.

FAQ’s

If you’ve read this far, then hopefully you’ve learned everything you wanted to know about the main differences between jointers and planers and have a good idea about which is the best one to use for specific woodworking tasks.

Yet if there’s anything you’re still unsure of, then you may find the answers you’re looking for in our FAQ below.

We’ve talked a lot about warping, twisting, and cupping throughout today’s guide, but if you’re relatively new to the world of the woodwork then these terms may be unfamiliar to you. Essentially, they describe certain deformities in your wood which are created by changing moisture content.

Let’s say you have one board that is stored in a room with a certain level of moisture All parts of that board soak up an even amount of moisture, but one part dries quicker than the other. Ultimately, the part that dries quickest also shrinks quickest, causing a change to the shape of the wood.

This can mean that was once a perfectly flat board is now bent, twisted, or cupped (having a groove in the middle of the wood), and is therefore unsuitable for use. The best way to prevent this from happening is to store your lumber in a cool, dry, and well-shared location. Rest your wood on a flat surface with heavy weights on top to prevent cupping.

Should your wood still become warped in some way, then using a jointer will get rid of that particular problem.

In terms of functionality, there really isn’t any different. A hand plane will do the same job as a motorized version but requires a certain level of skill that can take a whole lot of practice to acquire. With a machine, on the other hand, the learning curve isn’t nearly as steep so you can start achieving a great level of cutting accuracy very quickly.

Conclusion: Jointers vs Planers – Which One Should You Use?

So, with all that being said, is it better to spend your hard-earned money on a jointer or a planer?

Truthfully, this isn’t actually about choosing one over the other but, if your budget will allow it, getting your hands on both and using them to ensure your wood is perfectly prepared to be used for your next project.

If you only use a jointer, then you have no way of ensuring consistent and parallel surfaces. Even if you run it through the machine several times without making any adjustments, it’s extremely difficult to ensure the kind of precision you really need for your woodwork project.

This is why it’s such a good idea to use a planer as well as a jointer. After using the latter to square off one edge and set one surface to the required level, then you can use a planer to finish the job and replicate the same measurements across the board.

Of course, this begs one other very important question: Why not just forget about the jointer altogether and spend your money on a planer?

Simple: Even the best planers in the world won’t help you to square off edges, so if you’re planning to join multiple boards together, you’re going to need a jointer. Likewise, if your non-finished wood has cupping, warping, or twisting, only a jointer will be able to remove it so that your wood is usable.

Enjoyed this guide?

You might also enjoy our take on whether corded or cordless drills are better suited to your project, or why not check out our side-by-side comparison of two leading thickness planers, the WEN 6550 and the WEN 6552.